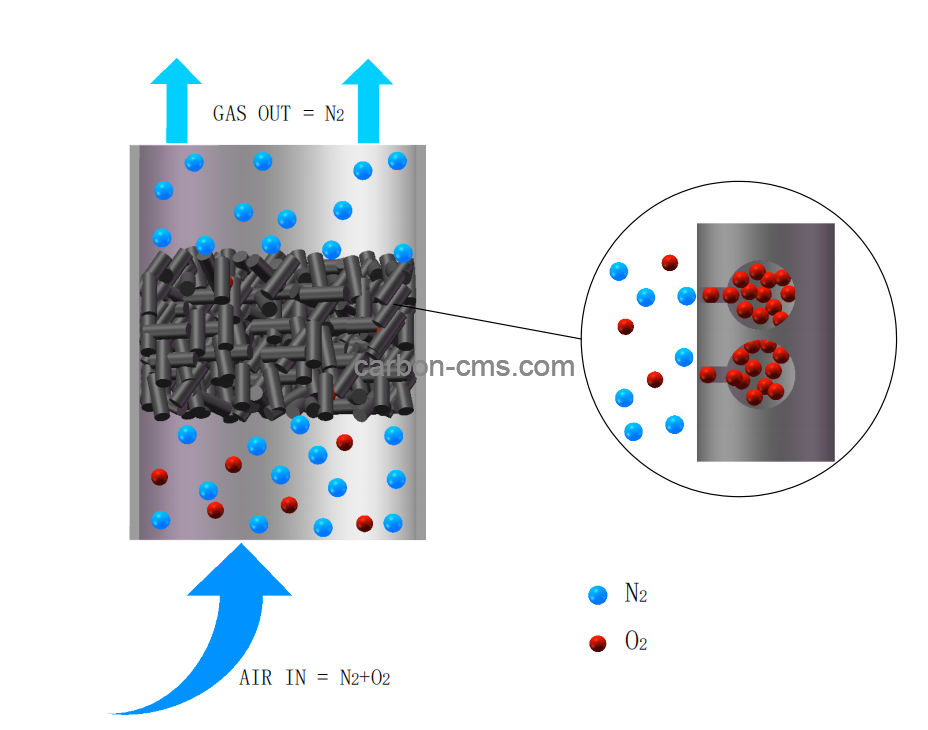

Activated carbon molecular sieve for nitrogen purification with PSA technology

Activated carbon molecular sieve(CMS) SLCMS-G1.3 is a new kind of adsorbent, which has the advantages of high concentration of oxygen enrichment and low air consumption.

Item No :

SLCMS-G1.3Shipping port :

Shanghai,Ningbo,Tianjin etc.Lead time :

3-5 daysAppearance :

Black cylindricalBulk density :

0.650-0.690g/mLCrush strength :

60N min.Diameter :

1.3-1.5mmAsh content :

5.0 max.Package :

20kg or 137kg per drumSLCMS-G1.3 Activated carbon molecular sieve for nitrogen purification with PSA technology

Technical Date

| Pressure:0.7MPa, Temperature:20℃, Cycle Time:2*40~45sec. | |||

| N2 Purity(%) | N2 Productivity(Nm3/hr.ton) | N2 Recovery(%) | Air/N2 ratio |

| 99.5 | 265 | 43 | 2.9 |

| For more technical parameters,please contact us. | |||

Carbon Molecular Sieve

The core advantage of carbon molecular sieves lies in their customizable pore size and excellent chemical stability, making them irreplaceable in the field of industrial separation, the micropores have a strong instant affinity for oxygen molecules and can be used to separate oxygen and nitrogen in the air. Nitrogen is produced industrially using a pressure swing adsorption(PSA) device.

At the same time, SHANLI unique micropore adjustment technology adds additional performance guarantee to the product, allowing it to perform well in various environments.

Efficient Gas Production Solutions

|

|

|

|

High Gas Production Output

|

Low Operating Cost For Gas Production | Extended Service Life Of Carbon Molecular Sieve |

| Our gas production system achieves high output levels, ensuring a reliable and efficient supply of gas to meet demanding industrial requirements. | The system is designed to minimize operational expenses through energy-efficient processes and streamlined maintenance requirements. | The carbon molecular sieve used in our gas production system has an extended service life, reducing replacement frequency and maintenance costs over time. |

Why Choose SHANLI?

--------------占位---------------

Our Certificates

|

|

FAQ

Can you provide samples? Is it free?

Can you provide samples? Is it free?

How is your CMS quality?

How is your CMS quality?

Copyright @ 2026 Chizhou Shanli Molecular Sieve Co., Ltd. All Rights Reserved.

Network Supported

Network Supported